This post is a part of our Making Clothes series.

Animal fibers come most obviously in the shape of various hairs, including wool. Also silk both from spiders and moths is used in various textiles. Feathers and down are sometimes included in animal fibers as well, but since their application tends to be incidental apart from decorative uses or as pillow or blanket fill, we will skip them here. (Sea silk is another rare but intriguing fiber we’ll skip.)

Sheep are probably the most common source for animal fibers for clothing use. Other common sources of animal hairs are goat (e.g. cashmere) and camelids (camel, llama, and alpaca), but even rabbit, cow, pig, or horse hair textiles exist. In Egypt, for example, extant fragments at the Workmen’s Village at Tel el Amarna (dated around 1350 BCE) included among others a small amount of wool textiles and two goat’s hair samples.

This post will first discuss sheep wool and then move on to moth silk.

WOOL

Wool is very common in pre-modern clothing. Sheep are not only easy to keep, they also provide different kinds of useful materials—wool, leather, bone and horn, gut, sinew, etc.—in addition to meat and milk.

Origins of Wool Production

Sheep grow their fleece out year round, and it serves them as insulation against cold, wet, and the hazards of the wild. (Note that fleece was originally just another name for sheep wool or certain woolly textiles; it was only after the introduction of synthetic fibers that polyester fleeces have become a thing).

Sheep were domesticated thousands of years before common era, most probably in multiple locations and/or episodes. The regions where domestication happened have been estimated to range from the Fertile Crescent to a large area from central Turkey to northwest Iran or to the Aralo-Caspian steppe. It looks like sedentary communities were practicing sheep management there already by 10000-8000 BCE. Following 7000 BCE or so, along with other elements of Neolithic life, humans spread domesticated sheep to neighboring regions, including Europe, northern Africa, and central Asia.

A sheep type bred to produce more wool came to Europe from the Near East or southwest Asia, along with the technology for wool processing during the 4th and 3rd millennia BCE. Around the same time, by 4000 BCE or thereabouts, camelids (camel, llama, alpaca, vicuña) were domesticated in the Americas, Africa, and the Arabian Peninsula.

Types of Wool

Modern sheep are the result of millennia of breeding. In the pre-modern world, sheep were smaller, and their wool was lighter in weight and less fine. In some places today there are heirloom breeds similar to sheep of antiquity, such as the North Ronaldsay sheep found today in the Orkney Islands.

Early sheep populations also typically had two wool layers with different qualities. Underwool, i.e. the innermost layer, is softer, as is lambswool. The overhair is longer, more resistant to water, and more hard-wearing. The separate layers have been bred out from many domesticated breeds; wild sheep populations, however, may still exhibit the feature. Wool quality also varies between individual sheep and between the sexes. The finest wool is found around the front shoulder blades and coarsest around the rump and leg areas.

Wild sheep tend to be brown, but Iron Age finds do also include black, grey, and white wool. The development of dyeing made breeding white sheep desireable. Conscious selection seems to have begun by Iron Age at latest, probably already earlier.

Collecting Materials

It’s plausible that when humans were first learning to use wool, it was collected by picking from the environment (and presumably also by removing it from carcasses). Once sheep were domesticated, plucking, combing, or shearing it off living animals became options.

Modern sheep are first sheared at about at 8 months of age, and after that, typically every 6 or 12 months, but even up to 4 times a year is possible. A professional can take as little as 2-3 minutes to shear a sheep, but with prehistoric tools the process must have taken much longer.

Processing Wool into Useable Forms

There are a number of pre-spinning steps that make it easier to turn wool into yarn. After fleece is collected, it needs to be sorted by type and quality. A modern fleece yields 5-7 types of wool. The wool is also washed to remove dirt, lanolin (the natural oil produced by sheep’s skin), and plant and fecal remnants. Depending on the intended use, some grease might be left in to retain its waterproofing qualities in the finished product or to aid spinning, because wool is easier to spin when some of the lanolin remains. Sometimes washing might take place before shearing, or if the sheared fleece was washed, it might be re-oiled.

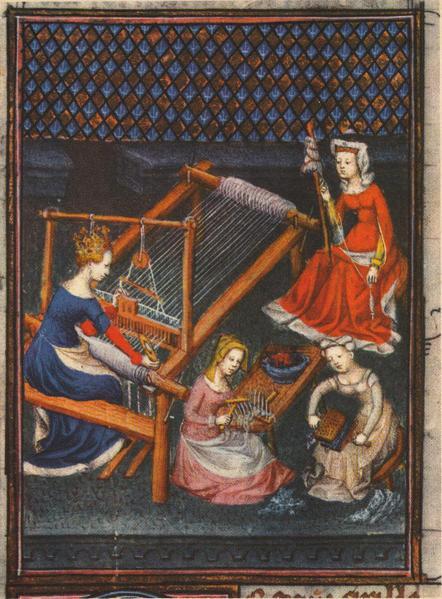

Cleaned wool is carded or combed (the terms sometimes seem interchangeable) using two combs or brushes to disentangle, straighten, and align the fibers.

Finally, clean carded wool can be spun into yarn ready for weaving, knitting, braiding, or other methods of textile production. Apparently, the earliest twill weaves are associated with wool (not linen), known from Anatolia in the 4th millennium BCE and the Caucasus in the early 3rd millennium BCE. Also the Hallstatt culture in Austria employed woollen twills during their Bronze Age (until approximately 1200-800 BCE) and Early Iron Age (800-400 BCE).

An example of the versatility of twill weave is the eye-catching diamond pattern, found for example in many Viking Age finds from Scandinavia. An early sample of diamond twill is found in the sleeves of the Lendbreen tunic from Norway (estimated to be from 230 to 390 CE).

Common alternatives to spinning yarn and weaving fabric from wool include felting, fulling, or using the fleece as is. Felt is made from interlocked fibers pressed together. Felting is technologically much simpler than weaving; in addition, coarser hairs that don’t spin well might be put to use in felted textiles. Friction and pressure is applied to fibers in conjunction with a wash, i.e., the fibers are somehow agitated or pounded in warm or hot water. (This should be a familiar concept if you’ve ever inadvertently shrunk a wool garment in the washing machine.)

For example, the earliest (2nd millennium BCE) attested textile remains from a cemetery at Qäwrighul in Xinjiang, northwestern China, include woollen samples, almost all of which are either felted or plain weave fabric.

One of the advantages of felt is that it doesn’t fray. Felt can also be dyed and/or embroidered, so a felted textile need not look boring.

Fulling is similar to felting, but it starts with woven wool fabric instead of loose fibers. At Hallstatt, most textiles dating from the Bronze Age are coarse, single-color, and made of thick wool yarn loosely woven using plain weave, with a surface often heavily fulled. Some areas in the world have retained their fulling tradition to modern times, e.g. the waulking in the Outer Hebrides.

Once fibers have been felted or fulled, it’s irreversible; therefore, attention must be paid while processing wool to avoid unintentionally ruining it.

Dyeing Wool

There is evidence of early people taking advantage of natural variations in wool colors to create various kinds of stripes or other motifs. (E.g. the Turfan rider’s pants from ca. 1200-1000 BCE used at least two different natural shades of wool.) Dyeing took that kind of decorative treatment to another level.

In Europe, for example the Bronze Age samples from Hallstatt that date to 1500-1200 BCE show multiple colors (blue, red, purple, yellow, green, brown, black) and variation in both dye selections and shades of wool. The popularity of blue and black shades there is perhaps based on the arresting contrast to the polished and shiny bronze and iron jewellery.

In the Levant, in southern Israel, woollen textile finds dyed red, blue, and yellow are dated to the Late Bronze and Early Iron Ages (13th-11th and 11th-10th centuries BCE), some even accompanied by tassels or beads. By 1000 BCE at the latest, dyeing wool was already so well established in the Tarim basin area (also in Xinjiang, northwestern China) that several finds include multiple colored fabrics, many of them multi-colored—plaids and brightly colored twills, for example, in yellows, blues, and reds.

Before dyeing, wool must be washed thoroughly, because lanolin may prevent the dyestuff from sticking onto the material or the results may become spotty. If using prewashed wool, the material must be wetted thoroughly and evenly for the same reason. Also, for an even color, large enough tubs and plenty of water must be used. A working estimate is to use 40 liters for 1 kg of wool yarn.

Typically, animal fibers absorb color more fully than plant fibers. However, animal fibers cannot tolerate extreme or sudden changes in temperature. Cool to cool-ish water must be used. If heating of the dye bath is desired, it must be done slowly, and care must be taken not just with temperature—keeping it below boiling—but also with stirring, squeezing, or rubbing for example while moving the material between containers, lest the wool felt.

Another detail to watch out when dyeing wool is that using the same dye batch on wools of different colors (white, off-white, grey, brown) results in different shades. Also, different types of wool may not take color the same way, nor (if they were added during spinning) will any so-called effect fibers from other animal species. As always when dyeing for a project, it’s advisable to dye all of the material at the same time.

Apart from the threat of felting, it is easier to achieve initial success when dyeing wool with natural materials than when dyeing plant-based fibers. However, stronger colors or certain more intense shades require overdyeing or multiple baths with different dyestuffs. For example, many Bronze Age and Iron Age textiles from Hallstatt show evidence of being dyed at least twice.

Regarding mordants or assists, also to note is that many plant-based ones tend to produce yellowy tones in wool, and that iron can easily make the texture rough and brittle. However, if urea was used for mordanting, the dyed product has to be washed and/or aired extensively to get rid of the strong smell. (And it still might not be enough, I understand.)

Typical Uses of Wool in Clothing

Due to its versatility and relatively easy production cycle, wool is an extremely common material. It’s probably true that if you can name an article of clothing, it’s been made from wool somewhere at some point.

Especially the coarser types of wool can feel rough against the skin. In many pre-modern cool clime grave finds (e.g. the Danish Huldremose woman from 2nd century BCE), there are remnants of plant fibers (linen, nettle, cotton, or the like) underneath wool remnants, so it looks like contemporary humans aren’t the only ones to prefer a softer layer next to their skin. Apart from the rough texture, wool is also susceptible to moths and carpet beetles, and direct sunlight will eventually damage the fibers.

Wool does make an excellent overlayer, though, because it’s warm even when wet. However, it doesn’t tolerate mechanical stress well, i.e., wool shrinks and felts easily. Depending on the processing methods used, wool can also resist water to some extent. This characteristic can be taken advantage of: for instance, when the grease is left partially in, when the fibers are felted, or when the fabric is fulled, the surface of the textile sheds droplets easily.

There are other features that make wool a good material for pre-modern contexts. The excellent insulation and absorbtion capabilities of wool makes it useful in warm to hot climates as well as cool ones. It’s a solid choice for utility textiles, too, because there’s a certain amount of elasticity in wool, which can help with the longevity and adjustability of wool items. Wool doesn’t wrinkle or ignite as easily and burns less well than plant fibers. Unfelted it also absorbs water (or other liquids such as sweat or urine) quite well. In addition, wool is relatively light and muffles sound. Wool has also been used e.g. as a wrapping for the deceased, and articles of clothing that have reached the end of their useful life have been repurposed as utility textiles such as sacks, bandaging, various kinds of wipes, or diapers or swaddling clothes.

SILK

Like wool, moth silk is an animal protein. The cultivation of silk (silk farming) is called sericulture.

Origins of Silk Production

Silk was certainly known for millennia prior to its appearance in historical records. For example, from Jiahu, Henan province, central China, there is biomolecular evidence of silk fibroin (a silk protein) found along with rough weaving tools and bone needles in tombs dated to ca. 6500 BCE. From the neighboring provice of Shanxi, from a Yangshao culture site, comes a find of cut silk cocoons dating back to between 5000 and 3000 BCE.

The earliest woven silk fabrics may have been used as wrappings of bodies for burial (two such samples from Henan province are dated to about 5000 to 3000 BCE). Other early scraps, including a remnant of a tabby weave from a Liangzu neolithic site in the Zhejiang province in southern China, date back to approximately 2750-2700 BCE.

By the Shang dynasty, 1600 to 1050 BCE or so, the domestication process had become highly developed, and silk weaving had achieved a very high level of quality. It is then we also find the earliest written records of silk (some oracle bone inscriptions) in China.

For a long time, from around 114 BCE to 1450s CE, the Silk Road—or Silk Routes—were the main network for cultivated silk trade between Asia and the Middle East, East Africa, and Europe. However, there were contacts even before that, for silk was found for instance in Egypt in a twenty-first dynasty mummy’s hair (1077 BCE to 943 BCE) and in a Ptolemaic-date (305 to 30 BCE) wollen tunic with decorative stripes with a weft of white silk. Around the same time, about 300-250 BCE, silk is encountered in Pazyryk in the Altai Mountains.

It is also possible that sericulture was developed independently and roughly concurrently in India. There is some evidence of processed silk fibers dating to about 2450-2000 BCE from Harappa and Chanhu-daro, two important Indus Valley civilization sites.

Types of Silk

The basic divisions of silk types are according to species of moths producing it, and according to fiber length and coarseness.

The domesticated silkworm or mulberry silkworm, Bombyx mori, is derived from a species native to northern India (Assam and Bengal) known as Bombyx mandarina Moore. These days most cultivated silk comes from Bombyx mori. The color of silk they produce ranges from white to cream white.

Tussah silk is a term for wild silk from Asia. Several species are commercially viable, for example some Antheraea or Saturniidae species, whose silk is sometimes referred to by geographical area (Chinese tussah, Indian tussah, etc.). Its texture is a little coarser and color darker than Bombyx Mori silk, from light to dark honey and beige, some even greenish or greyish.

There is also a species from another family of moths and butterflies, the Lasiocampidae Pachypasa otus, which produces a workable silk. Its present range is in the Mediterranean, and they were quite probably the source of the so-called silks of Cos of 5th century BCE Greece. For example, Aristotle (Historia Animalium 5.97.6 = 551b) describes the life cycle of a wild silk moth associated with Cos. Pliny the Elder (Natural History 11.76) describes a Syrian moth, which may be the same as the Coan one.

Silk is the only biological fiber that comes in long, continuous strands or filaments. (Some synthetic fibers, for example polyester and nylon, are also produced in filaments.) The kinds of domesticated silk fibers that are too short for regular processing are called waste silk. Wild silk is by default collected in smaller stretches, because the moth is allowed to emerge and break the cocoon. Both types of shorter silks can nevertheless be combed and spun.

(Rugs and other utility textiles are a good use for lesser-quality silks. Silk pile carpets are often exceptionally fine. For instance, the Baharestan Carpet was an enormous Sassanian work of art woven of silk, gold, silver, and rare stones. Kilims, on the other hand, could be put to work not just as rugs, but as wall art or other hangings, tablecloths, bedspreads, bags, or upholstery. )

Another division is between raw and processed silk. Technically, raw silk is any unprocessed form of silk that retains sericin, whether in unspun, yarn, or fabric state, but popularily the term is now often used to refer to raw silk fabric. Modern silks are classified to different grades according to quality, with A being the finest and F the poorest, with grades not eligible to rank below that.

Collecting Materials

Bombyx mori reproduce several times a year. Already by the Song dynasty, about 960-1270 CE, there were two or three annual silkworm harvests, but prized varieties could produce as many as eight generations in a single year.

After the Bombyx mori larvae hatch, they’re fed for about a month until they start spinning. Over two or three days, the silkworm secretes one continuous, fine fiber filament, approximately 300-800 m per cocoon.

After about 10 days from being finished, the cocoons are harvested, and hot air or steam is used to kill the pupae before they emerge as moths.

Wild silk moths are allowed to emerge and break the cocoon, which shortens the length of silk fibers collected.

Processing Silk into Useable Forms

Silk is a polymer composed of two types of proteins, sericin and fibroin. Fibroin is the structural center of the silk. Sericin is a gluey or gummy outer coating, and if it is removed, the fiber becomes easier to use. The process of de-gumming Bombyx mori silk by boiling or immersing in warm water developed at some point between 2500-2000 BCE.

Raw silk still contains some sericin; its presence makes wild silk a bit stronger than cultivated silk, but also heavier; therefore, raw silk fabric tends to have a more uneven, nubby, almost linen-like texture.

After the cocoons are de-gummed, filaments are stroked with a brush, chopstick, or fingers and collected onto reels. Long stretches of intact filament are unwound from cocoons (reeling) and twisted together (throwing) into multi-strand thread or yarn.

Some pieces of the cocoon are broken while harvesting and processing. For example, the coarse outside layers of cocoons, pierced cocoons (from moths allowed to hatch to lay eggs), or the leftovers remaining after reeling can be combed and spun for silk of lesser quality.

Silk is easy to spin because of its long fibers—the worm has a lot of the work already. Modern handspinners typically recommend fast and lightweight spindles and a lot of twist, especially for yarns meant for warp. Silk makes a high-grade yarn both smooth and strong with regard to its thinness, and it blends extremely well with other fibers.

However, silk fibers will catch easily on dry or rough spots on hands or nails, so using hand lotion or exfoliants (scrubs) is recommended for smooth spinning. Some spinner-suggested natural ingredients for skin softeners include olive oil, sugar, lemon juice, and sesame milk. Most of these would also have been available in prehistoric eras (depending on geography, of course).

It is difficult to find information on pre-industrial spinning speeds for silk. Presumably silk is about as speedy to spin by hand as wool. During the early years of the Warring States period (475-221 BCE), the so-called spindle wheel was developed. Although not a true spinning wheel as we know it, this device, where the spindle was driven by a belt (drive band), mechanized the reeling and throwing stages and helped to increase productivity by about three times.

Dyeing Silk

Silk has excellent dyeing properties, and early surving silk samples show evidence of dye work. By the latter half of the first millennium BCE at latest, there are dyed fabrics with detailed woven patterns or embroidery. (The collection at The Metropolitan Museum of Art even includes a 2nd century BCE fabric fragment with stencil printing and hand coloring.)

A male mummy found at a site in Yingpan, Xinjiang, northwestern China, and widely referred to as the Yingpan Man, dated to 266 to 420 CE, was accompanied by a host of stunning, high-grade wool and silk textiles, many of them ornately woven in what must’ve originally been vivid colors. Among those colors were yellow and green silks, plus red and brown both in silk and wool.

(Incidentally, the roots, bark, leaves, and berries of many mulberry cultivars can be used not just to feed the silkworms but also as natural dyes, which sounds very helpful for the early development of sericulture.)

Like wool, silk cannot tolerate extreme or sudden changes in temperature. It starts decomposing at about 170 degrees C. In dyeing, temperatures higher than 80 degrees C or so should be used with care, and only up to 140 degrees C at maximum. Silk requires more dyestuff to achieve deep or vibrant colors, because it dries two values lighter than when wet.

Typical Uses of Silk in Clothing

Silk is more heat-resistant than wool, but not impervious to fire. (Interestingly, the smell of burnt silk is similar to that of burnt hair.) Silk deteriorates with time, especially if sweaty or in sunlight, and might attract insects, especially if dirty. It’s also weaker when wet, tolerates strong detergents badly, and is susceptible to static cling in dry conditions.

On the other hand, silk is fine but strong for its delicacy, one of the strongest natural fibers. It has less elasticity than wool but more than cotton, which means that silk is elastic enough to be somewhat wrinkle-resistant. It absorbs moisture well—silk can absorb 30 % of its weight in liquid without feeling wet—and is a good insulator. Silk is also lightweight, soft, and shimmery.

Silk is a very versatile fiber mostly used for luxury fabrics both historically and now. (From my own experience I can say that silk satin is especially lovely and lustrous.) It’s been sewn into tunics, gowns, belts, mittens, socks, pillows, pouches, sachets, and wrapped as burial shrouds, among other uses. High-status uses include ecclesiastical vestments like the papal pallia.

Alternatively, silk was often used in embellishings such as ribbons, bands, or embroidery along with other fibers, even thin gold or silver thread. (An example is the Parthian remnant of a cotton-lined felt garment, likely for a child, with blue silk cord closure, from ca. first half of the 1st century BCE, currently held at The Metropolitan Museum of Art.) These were easy, relatively inexpensive ways to introduce some indulgence into your wardrobe.

How It Happens looks at the inner workings of various creative efforts.

You must be logged in to post a comment.