This post is a part of our Making Clothes series.

Our imaginary wardrobe is made up of four different kinds of material: wool, linen, silk, and leather. Each of these materials has a different origin. Today we consider the time, effort, and resources that went into producing the raw materials for each of these components.

Wool

Wool is processed from animal fleece, most typically sheep. Sheep grow their fleece out year round, and it serves them as insulation against cold, wet, and the hazards of the wild. Wool is traditionally gathered in the spring, so that sheep can have the warm summer months to regrow their coats.

There is no definite rule for how much pastureland it takes to raise sheep. Numbers depend greatly on the quality of the land and how it is managed. Modern farming experience gives us a rule of thumb that one sheep needs at least a hectare of land for a year’s grazing, although in historical conditions, the amount of land needed to raise sheep could have been significantly more.

Modern sheep are the result of millennia of breeding. In the pre-modern world, sheep were smaller, and their wool was lighter in weight and less fine. In some places today there are heirloom breeds similar to sheep of antiquity, such as the North Ronaldsay sheep found today in the Orkney Islands. One North Ronaldsay sheep yields between 1 and 1.5 kilos of fleece in an annual shearing. The shorn fleece loses some weight as it is cleaned and processed in preparation for spinning, from as little as 15 percent to as much as 80 percent.

Linen

Linen fibers are derived from flax, a woody-stemmed plant grown both for its fibers and for its oily seeds. Flax historically has been an important crop in many parts of the world.

Producing flax starts with plowing and sowing. An acre of land was traditionally defined as the amount of land that one farmer with one ox could plow in a day. Since a hectare is approximately two and a half acres, plowing a hectare of land in historic conditions would have taken about two and a half days. After sowing, flax plants take about 100 days to grow from seed to maturity.

Flax plants require deep, rich soil and draw lots of nutrients out of the earth, which means that fields repeatedly planted with flax will become exhausted in a matter of years. Sustainable flax production requires rotating with a less demanding crop and fertilizing to restore nutrients. Depending on fertilizer amounts, modern flax may yield between 4.9 and 7.8 tonnes per hectare. In historical conditions, dependent on animal manure or legume cultivation for soil maintenance, flax yields were unlikely to be as high.

Harvested flax requires extensive preparation to create usable fiber. The processing of flax removes 70-90% of the plant to yield fiber fit for spinning and weaving.

Silk

Silk fibers are derived from the cocoons of insect larvae, primarily the domesticated mulberry silkworm, although other creatures’ fibers have also been used historically. Domesticated silkworms are fed on mulberry leaves until they reach their fourth molt. The worms then spin cocoons by producing a long single filament which they wind around themselves.

It takes about 28 days from when silkworms hatch until they spin their cocoons. During that time, domesticated silkworms require careful tending and feeding, since most of their survival instincts have been bred out of them to make them more suitable for fiber production. They move very little and will not go in search of food if it is not provided for them.

Silkworms feed exclusively on the leaves of the mulberry tree. One mature tree produces enough leaves to feed about ten worms until they are ready to spin. Newly planted mulberry trees have to grow for about 8 months before they start producing leaves. To produce 1 kg of silk thread, 3,000 silkworms consume 104 kg of mulberry leaves, grown by about 300 trees.

Leather

Leather is produced from animal skins. A wide variety of different animals, both wild and domesticated, are used for leather. Domesticated mammals like cattle, sheep, goat, and pig yield most modern leather, although leather can also come from wild animals such as deer, squirrel, and rabbit, as well as non-mammals like ostriches, lizards, and fish.

The amount of leather that comes form one animal depends on the size of the animal and the condition of its hide. In modern leather processing, a typical cow hide yields 4.6 square meters of finished leather, while a sheep hide yields 0.8 square meters. Smaller animals naturally have smaller hides, and hides in poor condition may have to be trimmed smaller to be usable.

Skinning an animal after slaughter is relatively quick, but it is only the first step in leather production. The preparation, preservation, and treating of the hide takes many more steps that may amount to months of labor before the leather is ready to be cut, fitted, and finished.

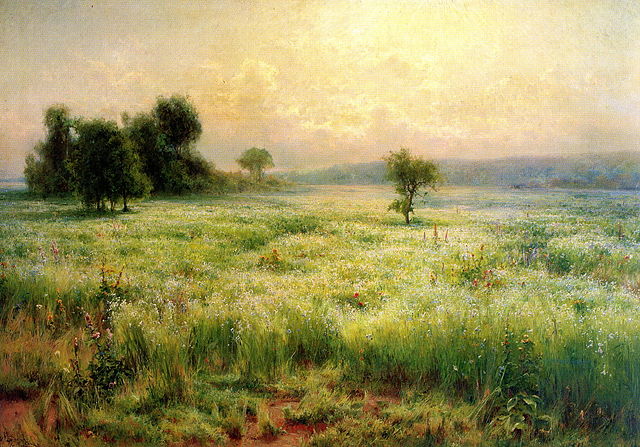

Images: Woman shearing sheep, from Book of Hours by Jehan de Luc via Wikimedia (currently The Hague; 1524; illumination). “Flax blooms,” photographed by Leonid Kulikov or Mykhailo Kvitka via Wikimedia (currently Fine Arts Museum, Kharkiv; 1893; oil on canvas; by Mykhaylo Berkos). Stamp of Afghanistan showing mulberry branch and silkworms via Wikimedia (1963; postage stamp) (this work is in the public domain under Afghan law). Leatherworking via Wikimedia (1568; woodcut)

How It Happens looks at the inner workings of various creative efforts.

One thought on “Making Clothes 3: Production of Raw Materials”

Comments are closed.